Cross-dock are pre-packed orders that arrive at the Distribution Center and need to be re-routed. Another case of cross-dock order is where the manufacturer ships directly to the retailer.

Cross-dock orders will not affect Inventory level, and will always allocate 100%. However, cross-dock orders are still required to be created, released, downloaded, updated, and shipped as a normal order.

Cross-dock orders is not included in the Master Order Entry report.

Step 1: Create Order

- Create a customer order as normal

- Select Order type Cross Dock

- Click Submit

Step 2: Release the order

Navigation: Orders > Release to DC

- The order will display (CD) after the Order ID to indicate it is a cross-dock order. Select the order to either Ship or Pack & Hold.

- Release

Note: When releasing cross-dock orders, it can only be filled 100% as it is not extracting information from your inventory level.

Tip: If you must ship a partially fulfilled order, reverse the order and edit the content. Create a separate order for the outstanding items.

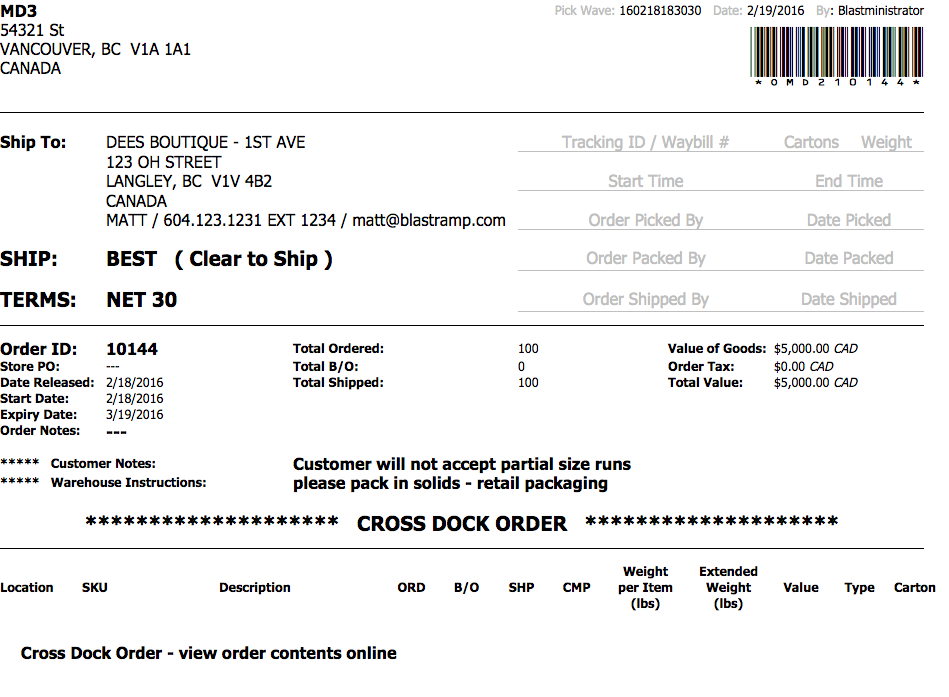

Step 3: Download the pick ticket

Navigation: Orders > Download Pick

- Proceed as you would for regular orders. Note that CROSS DOCK ORDER is clearly displayed on the pick ticket.

- Click the back arrow on your browser to continue onto the next step.

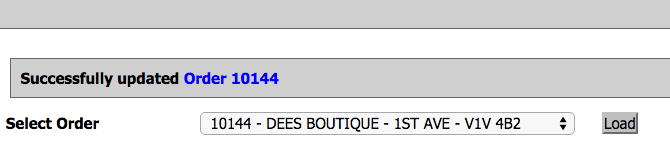

Step 4: Update the pick ticket

Navigation: Orders > Update

- Select the order from the dropdown > Load.

Because this is a cross-dock order, there is no picking, checking and packing, so the system autofills the Picked By, Checked By, and Packed By with "n/a-cross dock order". - All it is required is # of Cartons, Weight, and Freight Cost

- Click Update to complete.

- A Successfully updated message will display.

Step 5: Ship and Invoice the order

Navigation: Orders > Release PH or Ship

Release and Finalize same as regular orders.